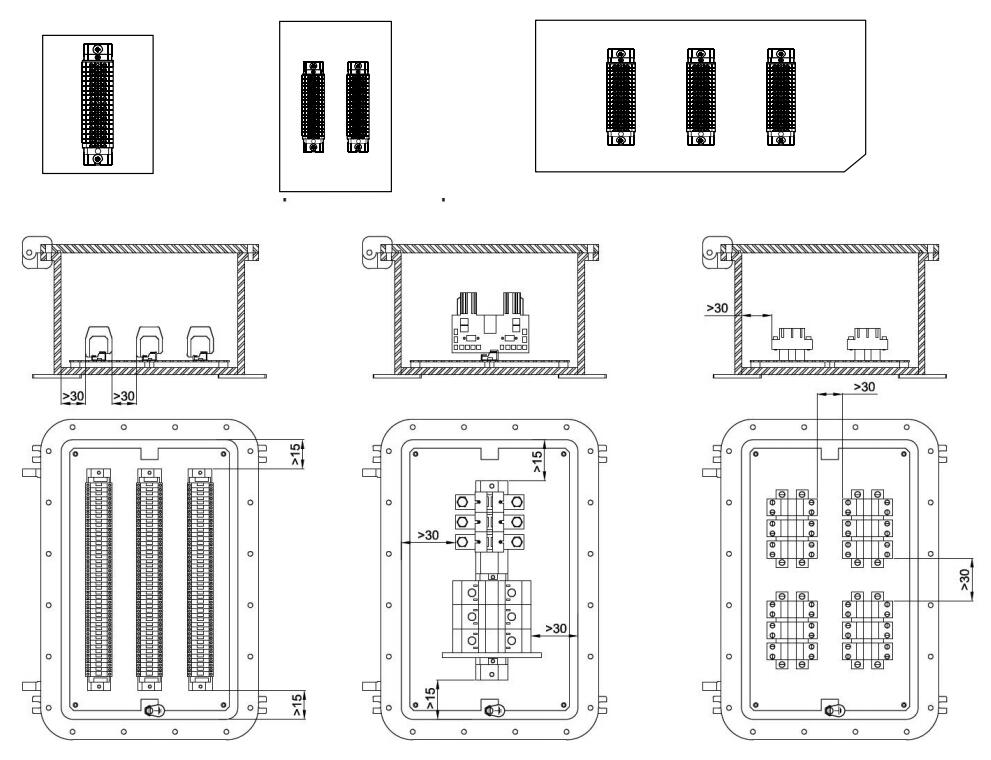

|

The enclosures EJB serie are normally installed in the industrial plants, with potential hazardous atmospheres of gases and combustible dusts, and therefore classified as Zone 1 - 2 - 21 -22. These enclosures are primarily used with the function of:

Enclosures for terminals and bus-bars.

Enclosures for fuses, trasformers, ballast and other electrical equipment with indipendent functionality.

Control stations and monitoring units.

Distribution boards for power and lighting systems.

Motor starters in variuos configurations.

Service hotline:

0523-88317000 88318288

-

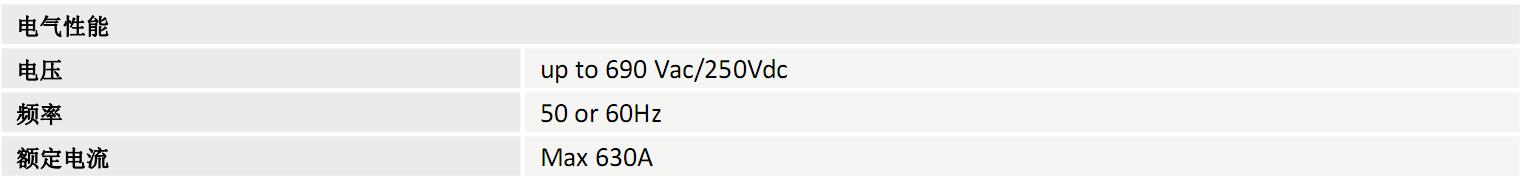

Rated values are maximum values, the actual electrical values are determined by mounted electrical apparatus.

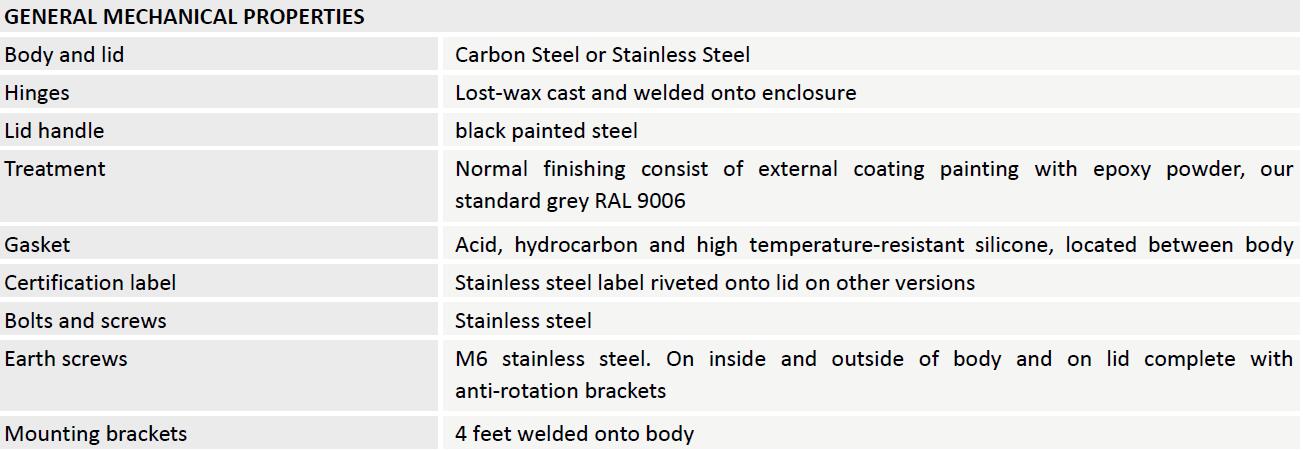

Accessories and special execution on request

?Special external coating painting off-shore, as per client specification

?Internal anticondensation coating painting, our std. Orange RAL 2004

?Special internal anticondensation coating painting, as per client specification

?Drain valve

?Breather valve

?Special hardware in stainless steel AISI 316 A4

?Out of standard thread

hread and hubs

?ISO 261/ISO 965 Metric thread

?ANSI-ASME B20.1 NPT thread -

A - Maximum external dimension B - Maximum external dimension

C - C - Maximum external dimension, depth D - Internal dimension

E - Internal dimension F - Internal depth

G - Fixing holes center H - Fixing holes center

J - Fixing holes diameter

K - Maximum external dimension with mounting bracket

X - Window dimension

Y - Window dimension [A] ... [D] - Entry faces -

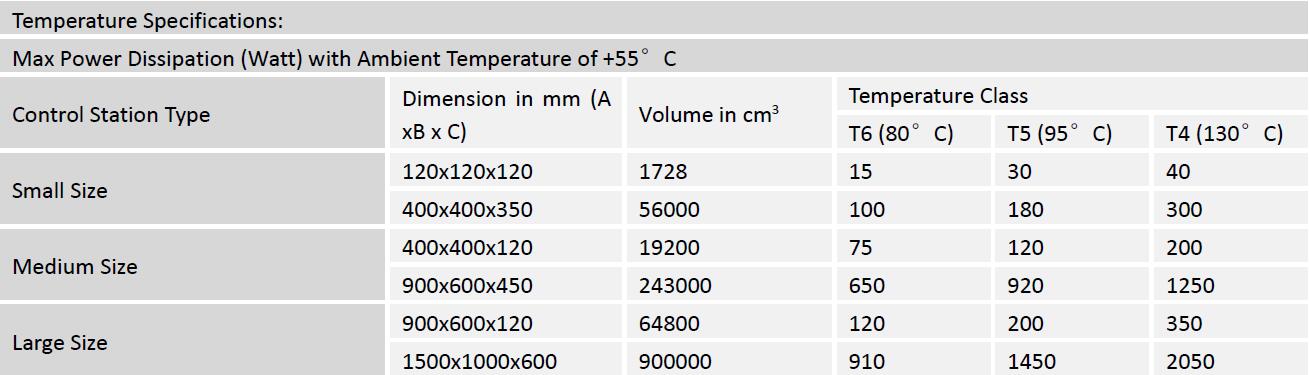

The junction boxes & control stations may also be manufactured to intermediate sizes. This assumes that anygiven dimension is not larger than the respective dimension of the largest enclosure or smaller than therespective dimension of the smallest enclosure. The power rating applied to a junction box of intermediate size isthat of the next smallest enclosure.

The terminal and components may be used in specified combinations subject to the calculation of maximumdissipated power and the conditions of certification listed. The maximum dissipated power for each enclosure isdetailed above.

The enclosures can be drilled and taped with the maximum size and maximum number of holes as specified in themanufacturer documents for the use with separately certified cable glands or blanking plugs.

Windows

According to the client request, in line with the maximum available dimensions, they are suitable a standardwindows for the various typologies of enclosures, windows for the most varied uses what visualization instruments,keyboard type "Touch screen".

X:80mm-250mm

Y:75mm-200mm

T=10mm -

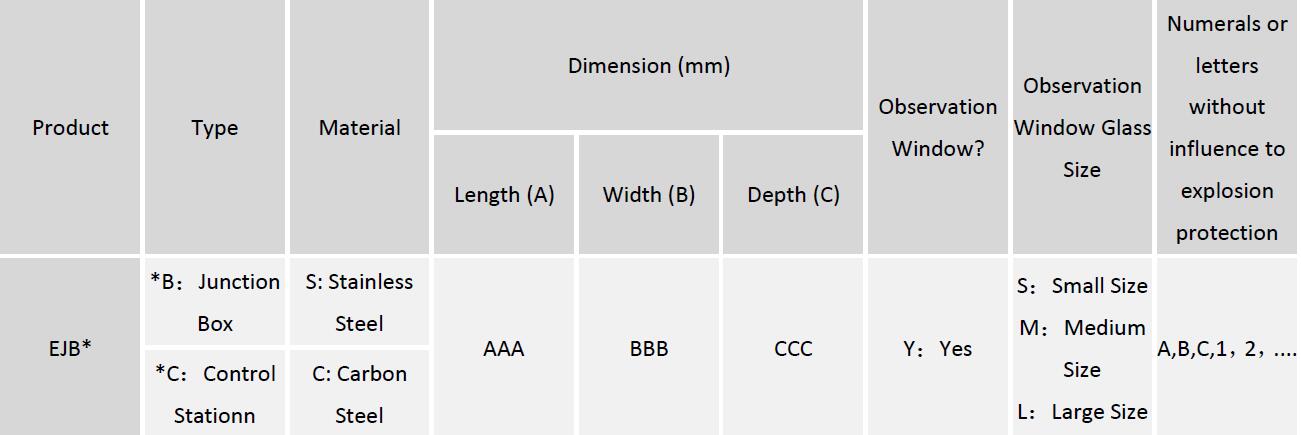

Please refer to the below table for ordering. If you need more information, please contact our sales representativefor assistance.

Ordering Table

Numerals or letters without influence to explosion protectionProduct Type

-

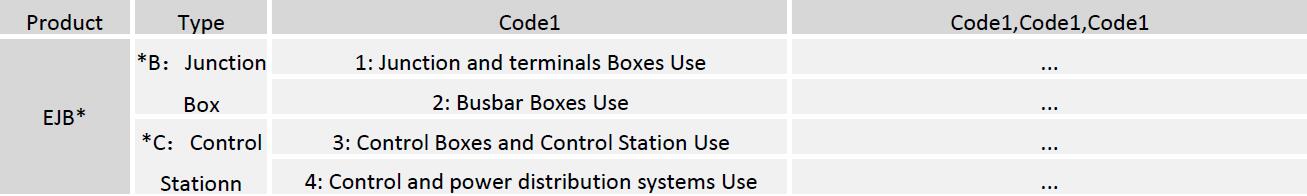

EJBB-S/C Enclosures for Junction and terminals Boxes use

These enclosures are primarily used with the function of cable termination unions, with terminals for derivation or change section cables, for joining long distance cables to terminals strips of motors and/or end users with entry

terminals of lower section.

The internal layout of the terminals can follow different configurations and, based on client’s special requirements

but always within the limits of the certificate of conformity, the terminals can be installed in different positions

compared to standard ones.

The size of enclosure to be used is done by our Technical Office on basis of several parameters indicated by the

client as:

? number and sizes of the cables

? number and sizes of the entries

? particular necessities regarding wiring and position of enclosures inside the plant.

If the enclosure is supplied complete with cable glands or sealing fittings, we’ll take care in dimensioning them

based on number and sizes of cable installed, besides to oversize the enclosure in case is required extra space for

future extensions.

The terminals are installed on mounting rails to be fixed directly on dedicated supports on the basement of the

enclosure or on its mounting plate.

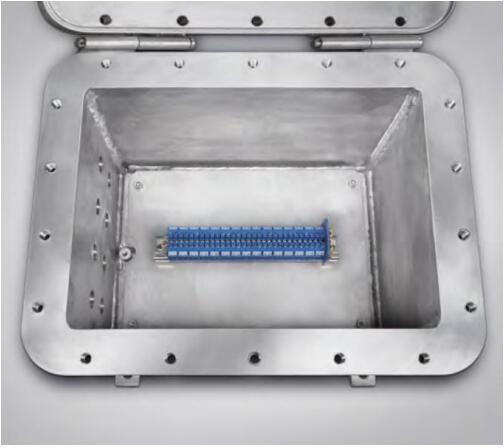

Examples of terminal disposition

The disposition of the terminals inside of the enclosure can be made in different configurations:

? straight

? diagonal

? on more rows

? on more rows and different levels

As per client request and always in the respect of the limits of certificate use, what maximum terminals, maximum

holes for side, least distance of pertinence and dissipable power for enclosure typology, the terminals can be installed in different positions from those on described.

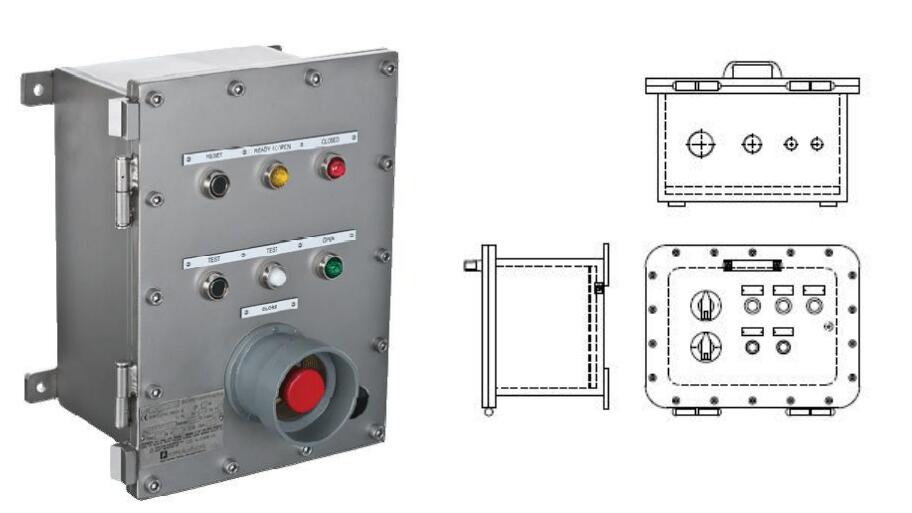

EJBC-S/C Enclosures for control and signal unit useControl, monitoring and signalling units are used to produce control boards that, when positioned near the electrical equipment being controlled, enable the electrical system to operate correctly and guarantee the safety of personnel when maintenance is being performed on the system. Because they are fitted with a Manual/Automatic selector, they allow operators to select the appropriate conditions to enable work to be performed entirely safely. They offer protection and control for electrical equipment and control circuits located in explosion hazard areas and in particularly aggressive environments. They are used to hold electrical equipment, such as switches, indicators, contactors, transformers, analogue and digital components, etc.... with the option of external control by using lid-mounted Dewei control and signalling devices, such as control levers, pushbuttons, indicator lights, etc.... Dewei designs, develops and supplies full cabling for one or more enclosures tailored to your specific requirements, producing panel boards - including even extremely complex solutions - and providing a full inspection and testing service on request.

EJBC-S/C Enclosures for power unit useA distribution cabinets type EJBC is made of steel with Ex d flameproof protection type. Closing of the cabinet is of threaded type and is protected against opening by lock switch, so that it can be opened only when it is not under voltage. The units is protected against corrosion by its painting inside and outside.

Ex d steel enclosures (type EJBC) and Ex e sheet steel enclosures (type EJEC-S) can be used as single enclosures and combinations.

The dimensions of the enclosures are so designed that they can be combined into a large modular unit. A large number of components, such as contactors, switches, instruments and PLCs can be built into these enclosures. Naturally, customer- supplied equipment can also be incorporated into the layout. The equipment layout is designed by us to customer's requirements. Cable entry is either direct (cable glands or conduit entries) or indirect via an Ex e enclosures type EJEC-S.

The "flameproof" type protection 'Ex d' is based on the principle that electrical components which may cause sparks or arcing in normal operation (switches, contactors etc.) are in an enclosure constructed so that it will contain an explosion of flammable gas or vapor and will not permit ignition of a surrounding explosive atmosphere.Further, the temperature of the outside surface of the enclosures must not exceed the prescribed temperature limit for the appropriate temperature class. That means, the heat loss from the components fitted must not exceed a specified value.

Data required for the layout of control and distribution boards

We produce distribution cabinets accordint to customer requirements and basis to the project data:

? the required minimum type of protection

? as appropriate, details of the hazardous atmosphere for which the equipment must be suitable

? single line or wiring diagram

? schematic for control systems

? operating, auxiliary and control voltages

? frequency

? power and current ratings of connected loads

? quantities and types of components required, e.g. contactors, switches, circuit-breakers, fuses, thermal relays,instruments, terminals etc

? quantity and types of cables

? number and size of conductors

? quantity and location of entries (from top, bottom, side, centre)

? environmental conditions

? method of installation

|

Please write what you need, we will contact you asap!

Give technical advice within 30 minutes | Provide program design within 24 hours | Send domestic / foreign engineers within 24/72 hours

|