|

|

|

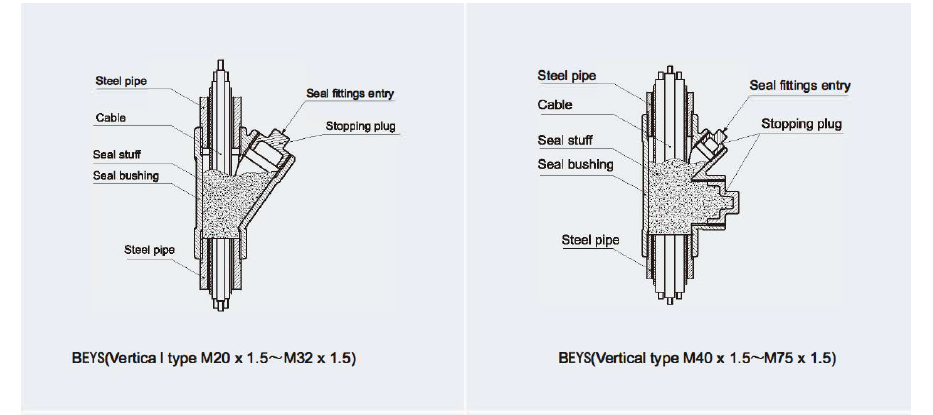

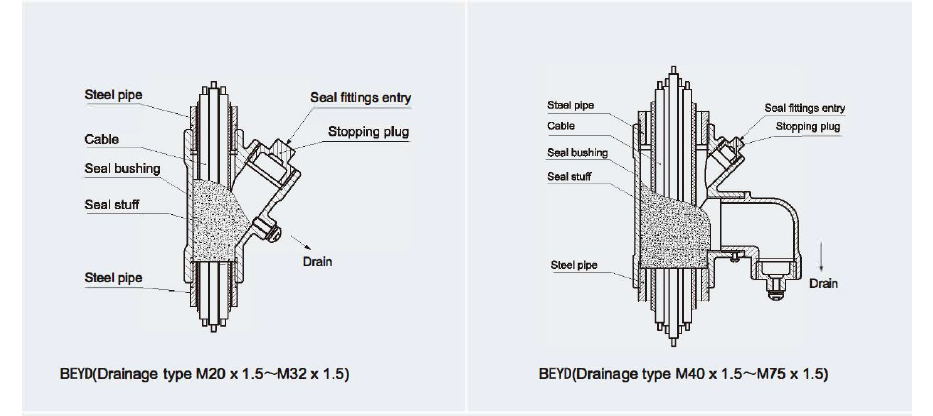

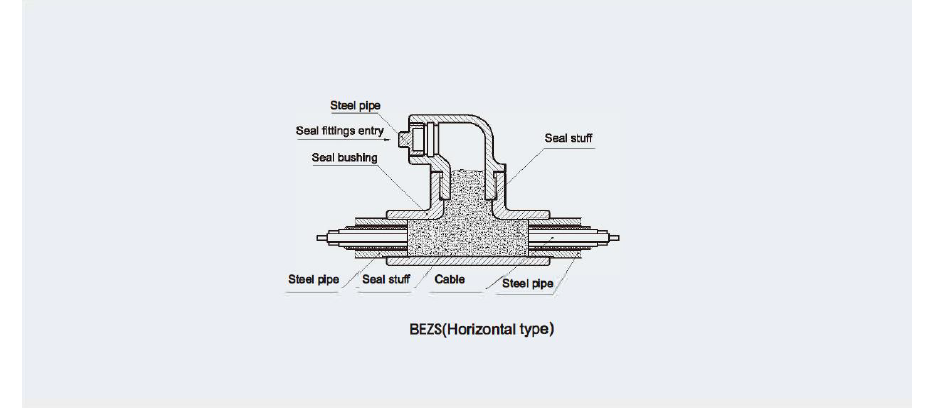

Restrict the passage of gases, vapors or flames from one portion of theelectrical installation to another at atmospheric pressure and normal ambienttemperatures.

Limit explosions to the sealed off enclosure.

Limit precompression or pressure "piling" in conduit systems.Sealing fittings are required.

At each entrance to an enclosure housing an arcing or sparking device whenused in Class I, Division 1 and 2 hazardous locations.To be located as close as practicable and, in no case, more than 18" from suchenclosures.

At each conduit entrance of 2" size or larger to an enclosure or fitting housingterminals, splices or taps when used in Class I,Division 1 hazardous locations. Tobe located as close as practicable and, in no case, more than 18" from suchenclosures.

In conduit systems when leaving Class I, Division 1 or Division 2 hazardous locations.

In cable systems when the cables either do not have a gas/vaportight continuous sheath or are capable of transmitting gases orvapors through the cable core when those cables leave the Class I, Division 1 or Division 2 hazardous locations.

Service hotline:

0523-88317000 88318288

-

? Suitable for use in Zone 1, Zone 2, Zone 21, Zone 22 and in Gas Groups IIA, IIB and IIC.

? Construction and Test Standards: IEC/EN 60079-0, IEC/EN 60079-1, IEC/EN 60079-7 and IEC/EN 60079-31.

? Ingress Protection: IP66, IP67 and IP 68.

? Operating Temperature Range: -60°C to +140°C.

? Material: brass, nickel plated brass or stainless steel 304、316L.

? Ex-marking: II 2 GD Ex d IIC Gb Ex e IIC Gb Ex tb IIIC Db IP68

Ex d IIC Gb Ex e IIC Gb Ex tb IIIC Db IP68

-

-

-

|

Please write what you need, we will contact you asap!

Give technical advice within 30 minutes | Provide program design within 24 hours | Send domestic / foreign engineers within 24/72 hours

|