Dewei offers the enclosure series EJPZ in different sizes and designs.

All systems are available for the use in hazardous area ( and Zone 2/22) in the protection type over pressure. Variants can vary depending on the specific application. The enclosure series EJPZ allowed the customer to bring his non ex- components directly in the hazardous area.

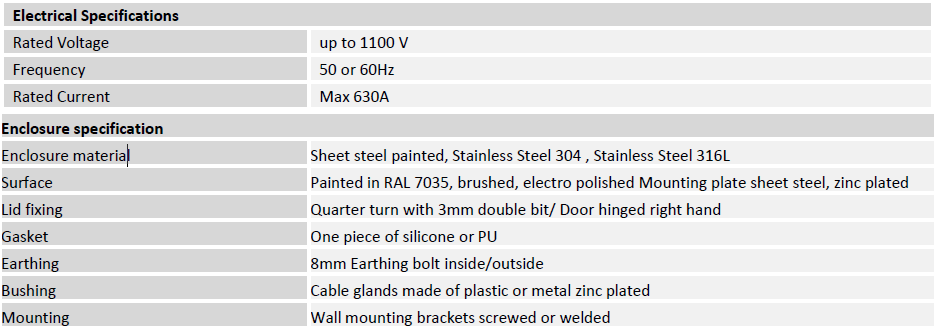

Type EJPZ Series Explosion-proof Pressurized Distribution Cabinets consists in pressurized enclosure and Ex p control unit. The pressurized enclosure consists in a cabinet with different enclosure sizes as specified in the manufacturer document and a pressurization system as associated apparatus. The pressurized enclosure is of high quality carbon steel and stainless steel ,Using the sealing strip. The Ex p control unit type will be used to control and verify the minimum over pressure, to perform the purging of the enclosure, to control the purging and pressurization alarm.

Service hotline:

0523-88317000 88318288

-

Description:

The control unit are fitted various devices including an air filter/reducing valve, mechanical pressure gauge, flow control valve,pressure sensor, The timing device, Exd e light fittings, Ex mb solenoid valve and Exd control station which have standard electrical components. The combined main enclosure and Exd control station form the purge control unit.

The equipment also comprises a pressure relief valve assembly,incorporating orifice plates, which determine purging gas flow rate and an over pressure protection. Purging gas exits the unit via a stainless steel wire mesh spark arrestor.

The allowed protective gas is: nitrogen, argon, carbon dioxide, helium or instrumental compressed air as specified in the marking plate. There is no internal source of flammable gas release allowed. Multiple pressurized enclosures up to 10 m3 of total internal volume are also possible as specified in the manufacturer document.

-

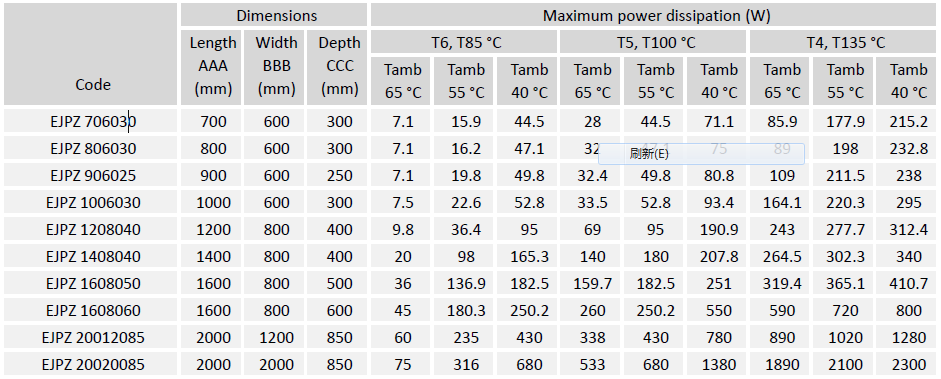

The enclosures may also be manufactured to intermediate sizes. This assumes that any given dimension is not larger than the respective dimension of the largest enclosure or smaller than the respective dimension of the smallest enclosure. The power rating applied to a enclosures of intermediate size is that of the next smallest enclosure.

The terminal and components may be used in specified combinations subject to the calculation of maximum dissipated power and the conditions of certification listed. The maximum dissipated power for each enclosure is detailed above.

The enclosures can be drilled and taped with the maximum size and maximum number of holes as specified in the manufacturer documents for the use with separately certified cable glands or blanking plugs. Each enclosure is provided with an internal earthing certified terminal or earthing point. Metal enclosures are provided with an external earthing point. Commercial electrical apparatus of all sorts can be fitted into pressurized cabinets.

Electrical interlocking device, to reach the stipulated time of ventilation to automatic transmission, and low-pressure automatic alarm and automatic gas supplementary device and high - pressure self closing function.

The sealing performance is reliable, the shell adopts the multiple seal protection, and the holding time is long, and the operation cost is saved. When the user needs to be equipped with clean or inert gas source. This product requires steel pipe or cable wiring.

Modular building system allows to realize customized volume up to 10m3. One of the system that offers the widest possibilities on the market. A single system of pressurization and washing can manage multiple modules in series.

New gasket technology minimizes the dispersion of inactive gas, increasing efficiency of pressurized system and reduce operating costs EJPZ pressurized panels, because of the continuous influx of purging gas, prevents the build up of heat and moisture and provide a greater life cycle of the equipment.

Quick access: easy opening and maintenance, when the doors open the system disconnects; when the doors are closed again, after the washing cycle, the system will start again automatically.

The configurations for electrical components on the control panel of the control box cover and inside the control box enclosure can be customized to meet the requirement of customers. -

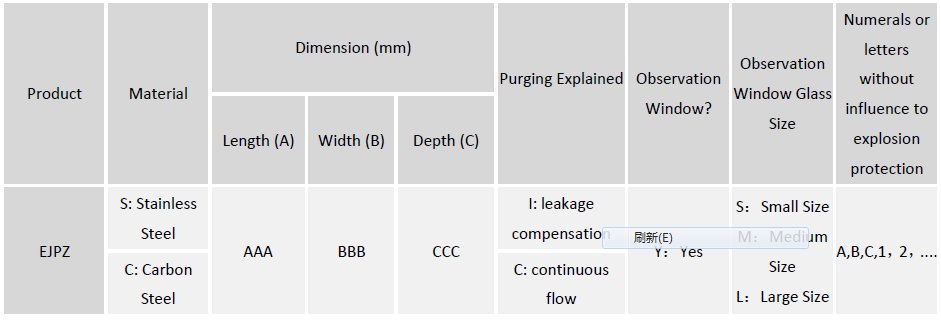

Please refer to the below table for ordering. If you need more information, please contact our sales representative for assistance.

|

Please write what you need, we will contact you asap!

Give technical advice within 30 minutes | Provide program design within 24 hours | Send domestic / foreign engineers within 24/72 hours

|